Materials & Radiation Effects

Radioactive materials and the response of materials to radiation are important to nuclear power, space technology, and fundamental science.

The progress of any technology depends on the performance of the materials it employs.

Materials used in nuclear technology suffer from degradation due to radiation. The goal of the research on nuclear materials is to understand the effects of radiation and use the knowledge gained to improve materials resistance for applications in energy production or storage of radioactive materials.

The changes that occur in materials by radiation can also be exploited to develop materials with special properties that cannot be achieved by conventional methods of synthesis. This has opened up new areas of research involving the use of radiation effects and radiation-based techniques for materials synthesis and characterization.

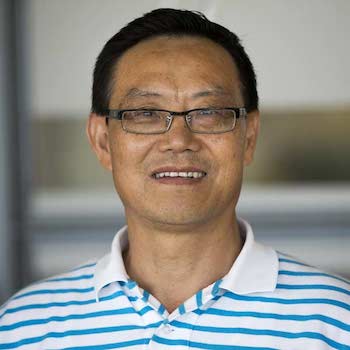

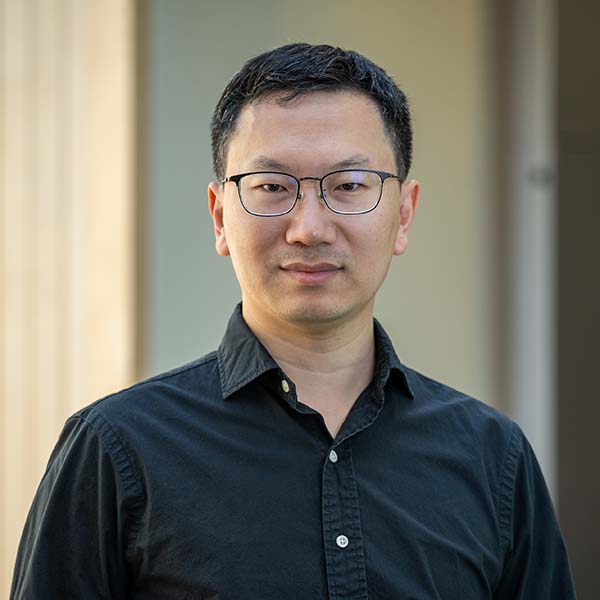

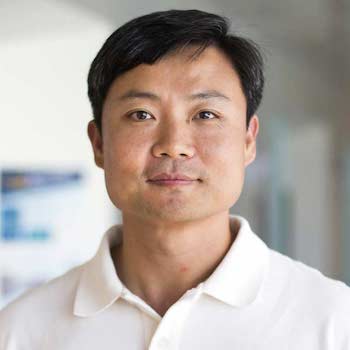

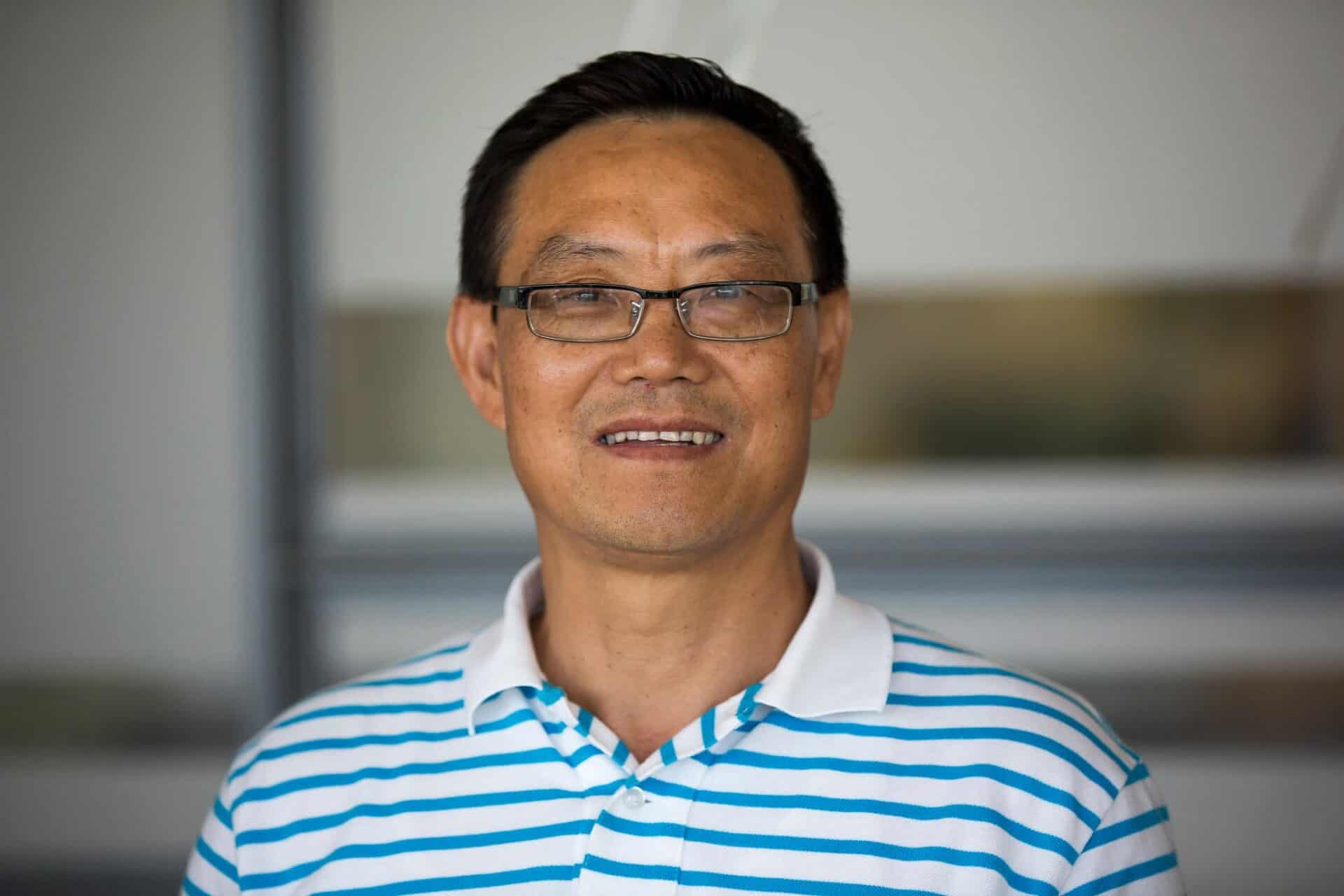

Faculty

Labs & Groups

| Computational Nuclear Materials Group (Prof. Fei Gao) |

| High Temperature Corrosion Laboratory (Prof. Stephen Raiman) |

| Irradiated Materials Testing Complex (Prof. Stephen Raiman) |

| Materials in High-Temperature Extreme Environments (MiHTEE) Group (Prof. Stephen Raiman) |

| Materials Preparation Laboratory (Prof. Lu-Min Wang) |

| Metastable Materials Laboratory (Prof. Michael Atzmon) |

| Michigan Center for Microstructure Characterization (Prof. Gary Was) |

| Michigan Ion Beam Laboratory (Prof. Kevin Field) |

| Nuclear Oriented Materials & Examination Group (Prof. Kevin Field) |

| Radiation Effects and Nanomaterials Laboratory (Prof. Lu-Min Wang) |

| Radiation Materials Science Research Group (Prof. Gary Was) |

| Z-Lab (Prof. Y Z) |

NEWS

GET INVOLVED

We believe that engaging in research as an undergraduate student is a very important part of the NERS experience, and many of our third- and fourth-year undergraduate students are actively involved and have co-authored papers in scientific journals.