Kevin Field and Stephen Raiman named new directors of NERS materials labs

The founder and original director of the three labs, Gary Was, stepped down on July 1.

The founder and original director of the three labs, Gary Was, stepped down on July 1.

Gary Was, who officially retired from the U-M Department of Nuclear Engineering & Radiological Sciences (NERS) in 2021, has stepped down as director of three of the labs that he founded during his storied tenure with the department.

Kevin Field, an associate professor with the department since 2019, is now the director of the Michigan Ion Beam Laboratory (MIBL). MIBL will continue to be managed by Zhijie Jiao, who assumed the role in 2021 after long-time manager Ovidiu Toader retired.

Stephen Raiman, an assistant professor with the department since 2022, is now the director of the High-Temperature Corrosion Laboratory (HTCL) and the Irradiated Materials Testing Laboratory (IMTL). Both labs will continue to be Managed by Connor Shamberger.

“First-class research deserves first-class research facilities,” said Was. “The Michigan Ion Beam Laboratory and the corrosion laboratories in NERS were designed to provide students with the most modern facilities and capabilities in their respective fields. The goal was also to train students on instrumentation at the level of sophistication of the national labs to make transitions easier. But it was also a labor of love for me for the last 41 years that was only possible with the support of the Department and the College, and the many students, post-docs, and researchers who helped to build them. I have to say that I couldn’t be happier passing on the care and future of these facilities to two such outstanding young scientists. I have no doubt that Kevin Field will not just maintain but grow the capabilities of MIBL. I have already seen his zeal for creating new capabilities at MIBL. And I am as excited to put the corrosion labs in Stephen Raiman’s most capable hands, as he also has brought new ideas, techniques, and scope to those labs in addition to supporting their original missions. With Kevin and Stephen, the Department can look forward to an outstanding future for nuclear materials at Michigan.”

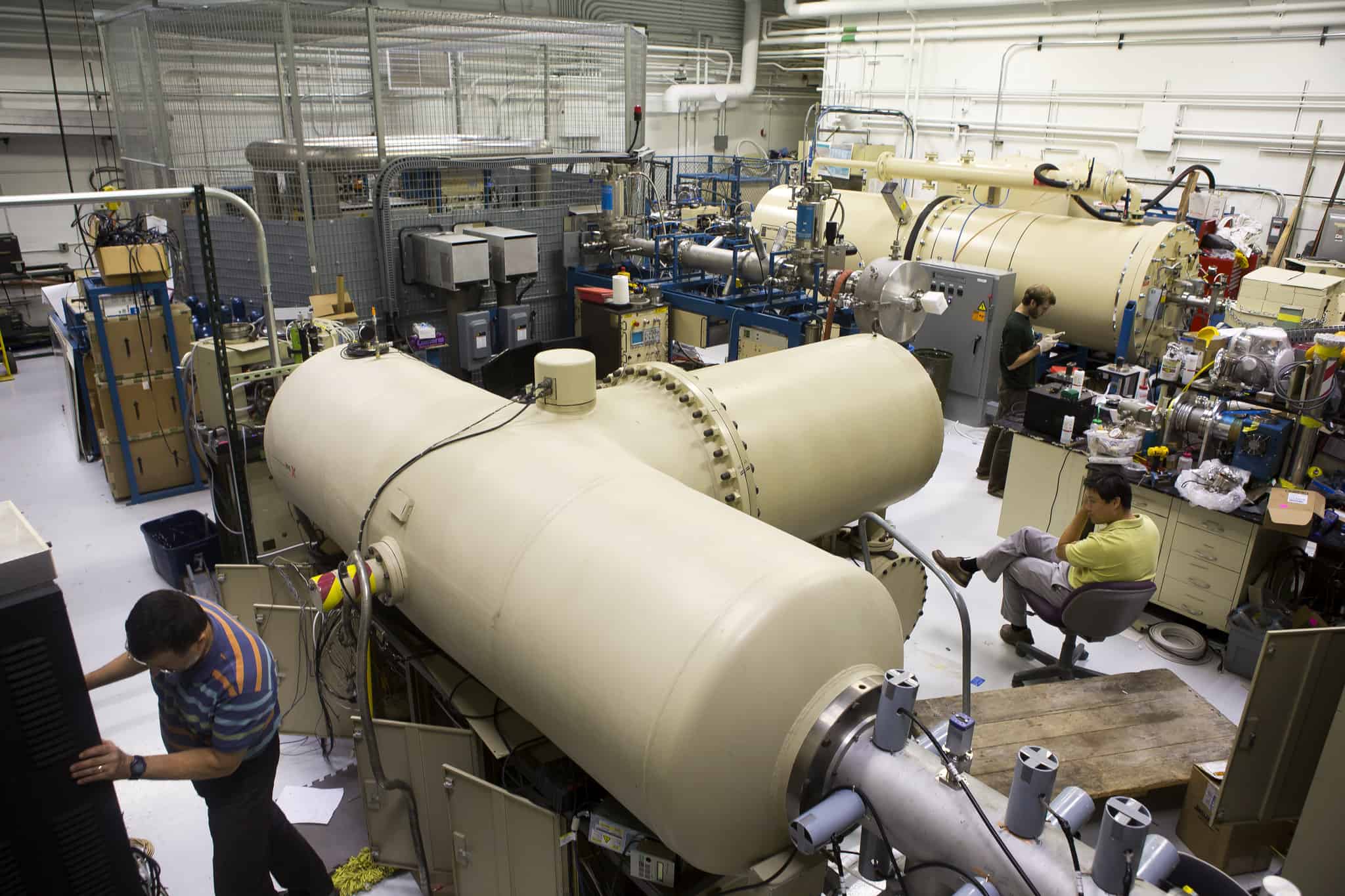

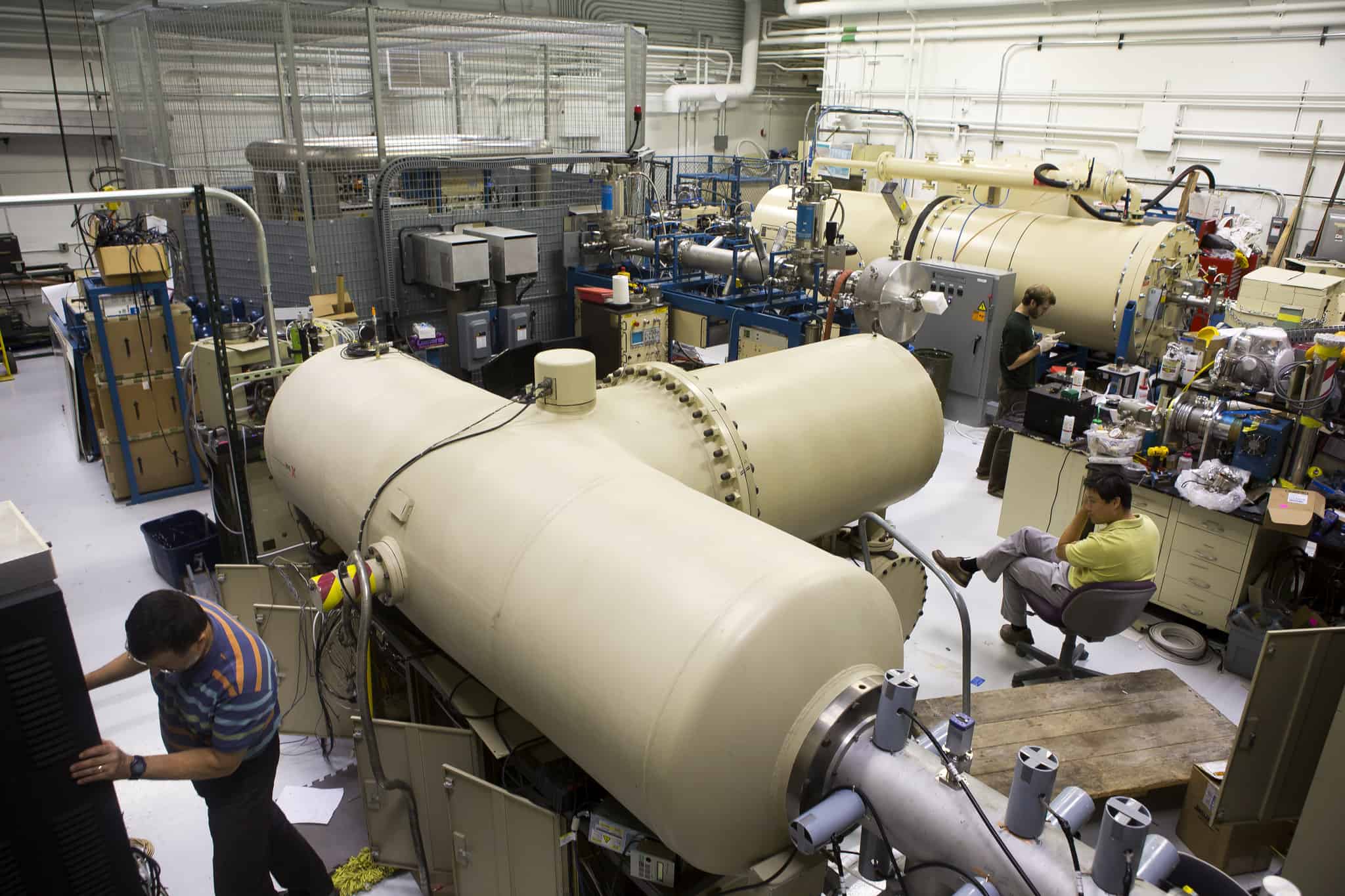

The Michigan Ion Beam Laboratory, or MIBL, is an experimental user facility that is unparalleled by other universities or even at our country’s national labs. It was established with a single accelerator in 1986 to advance our understanding of ion-solid interactions. The lab grew to include two accelerators and an ion beam deposition system for studying the effect of ion irradiation on deposited films and coatings. The advent of GenIV nuclear power systems and corresponding programs saw an increased interest in the use of ion irradiation to study radiation damage in reactor core components. With the award of a DOE IRP in 2013, the lab underwent a major expansion in 2014-15 to house a third accelerator providing the only capability in the U.S. to conduct triple beam irradiations. Computer control of the accelerators and the addition of a 300 kV transmission electron microscope (TEM) connected to two beamlines for in-situ irradiation in the TEM has made MIBL a unique facility in the US and worldwide. Since the late 1980s, Was has been a key developer of using ion irradiations to study radiation effects such as swelling in materials for nuclear power systems. MIBL has been central to this source with seminal findings on the use of proton irradiations to simulation radiation-induced segregation and, in recent years, the development of dual-beam ion irradiation methods to emulate fast neutron swelling. The facility is also closely coupled to the corrosion labs with in-situ corrosion experiments and is a critical resource for studying the influences of irradiation on stress corrosion cracking of iron- and nickel-based alloys in the extreme environments of nuclear reactor cores.

MIBL has been a U.S. Department of Energy Nuclear Science User Facility (NSUF) since 2009 and is used by researchers worldwide. MIBL on average performs over 4500 accelerator hours annually across its three primary accelerators and serves over 100 unique users annually. Users come from all different types of backgrounds and research/engineering needs including from other universities, government laboratories, and industry. MIBL has been a resource for launching the storied careers of many nuclear materials scientists and engineers through both Prof. Was and the NSUF with MIBL alumni at most major national laboratories, at nuclear startups such as Kairos Power, and leading universities across the nation.

“I had a chance to tour MIBL in graduate school,” said Field. “At that time, I was impressed by the laboratory and the sheer amount of research ongoing at MIBL. Now, a decade later I walk in every day and I am still impressed. Professor Was has built one of the leading facilities to do radiation effects testing and evaluation. These facilities will be critical for getting advanced fission and fusion power plants on the grid in my lifetime. I am excited that I had a chance to learn from Professor Was and continue the legacy that MIBL has on our energy landscape in the US and abroad.”

The Irradiated Materials Testing Laboratory, or IMTL, and the High-Temperature Corrosion Laboratory, or HTCL, are also Nuclear Science User Facilities. At IMTL researchers can conduct high-temperature corrosion and stress corrosion cracking of neutron-irradiated materials to understand the effects of irradiation on corrosion and cracking. Equipment in the lab includes five high-temperature autoclaves, each with a circulating water loop, load frame, and servo motor for conducting constant extension rate tensile (CERT) and crack growth rate (CGR) tests in subcritical or supercritical water up to 600°C. Hot cells are available for experiments with radioactive materials taken from test reactors and commercial reactors.

HTCL gives researchers the ability to conduct corrosion, stress corrosion cracking, and hydrogen embrittlement tests of non-irradiated materials in high-temperature aqueous environments and, in particular, simulated light-water reactor environments. The corrosion laboratory has unique facilities for conducting both high and low-temperature corrosion, stress corrosion cracking (SCC), electrochemical testing, and mechanical testing.

Together, these laboratories are used to advance our understanding of how materials degrade in nuclear reactors. IMTL and HTCL researchers help to provide the evidence basis for ensuring the safety and economy of our current light water reactor fleet while helping to develop new materials for future reactors.

“Professor Was is a giant in the world of nuclear materials, and the labs he built are part of his legacy,” said Raiman. “Even more important are the generations of students who trained in these labs, who can be found throughout academia, our national laboratories, and in high-impact positions in industry. I am humbled that Professor Was has entrusted me with stewardship of IMTL and HTCL, and I look forward to maintaining our department’s reputation as a world leader in this field. Future generations of students will continue to benefit from training in our world-class corrosion laboratories.”

“Professor Was built a world-leading experimental capability that increased our knowledge of materials performance in nuclear systems,” said NERS Chair Todd Allen. “His work was a major contributor to the #1 ranking of the department and the international research community is well-represented by his former students. We are pleased that two such capable young faculty are ready to build on that legacy.”