Matthew Lynch and Justin Hamil receive NSUF funding for materials research

The NERS graduate students will research a novel high-throughput method for quantifying radiation-induced material swelling using microscale dilation techniques.

The NERS graduate students will research a novel high-throughput method for quantifying radiation-induced material swelling using microscale dilation techniques.

NERS graduate students Matthew Lynch and Justin Hamil have been awarded funding from the Nuclear Science User Facilities (NSUF) to advance their research on quantifying materials swelling in high-radiation environments.

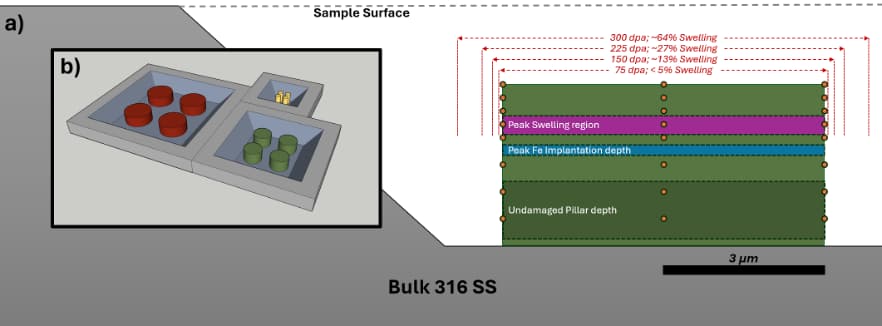

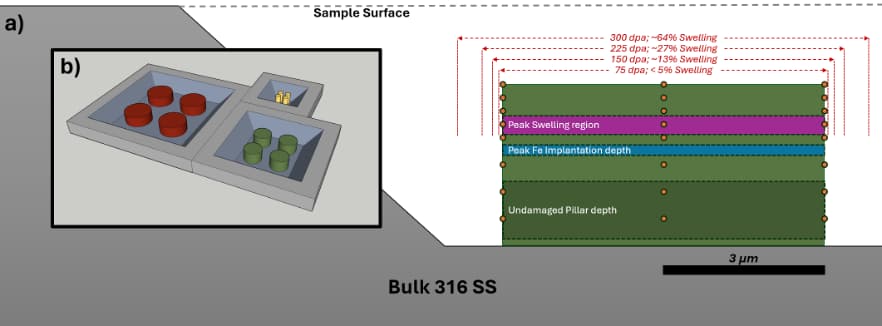

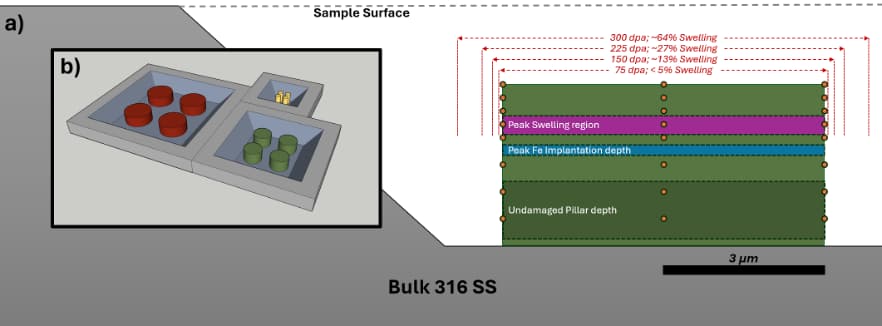

Matthew Lynch, a fourth-year PhD candidate, and Justin Hamil, a first-year PhD pre-candidate, are leading a project titled “A Novel High-Throughput Method for Quantification of Materials Swelling via Microscale Dilation Techniques,” alongside their advisor, NERS Prof. Kevin Field. The project aims to develop an efficient method to measure radiation-induced swelling in materials, a significant degradation pathway in advanced nuclear reactors.

The team’s approach leverages pre-irradiation fabricated micrometer-scale pillars on sample surfaces to measure volumetric swelling, significantly reducing the time and cost associated with the traditional method of focused ion beam (FIB) milling of transmission electron microscopy (TEM) lift-outs. Using customizable arrays of micropillars and scanning electron microscopy (SEM) for post-irradiation analysis, this method could enable high-throughput, statistically significant data collection. This innovative technique enhances the ability to analyze a broader range of irradiation conditions and material classes, holding significant potential for improving the development and qualification of materials for advanced nuclear reactors, ultimately contributing to safer and more efficient nuclear energy systems.

“If successful, this technique will alleviate some of the time-intensive and financially costly aspects of our research,” said Hamil. “It could be an excellent technique to rapidly down-select materials that swell after they are exposed to high doses as they would at the end of life in new reactor designs.”

“This project is exciting because it’s prompting us to look at a ubiquitous technique in the field, and ask what are its shortcomings and how can we improve upon them,” said Lynch. “We’re being challenged by new material and experimental conditions, such as free surface effects, and being pushed to use our tools in novel ways.”

The research will be conducted using state-of-the-art facilities here at U-M, including the Michigan Ion Beam Laboratory (MIBL) and the Michigan Center for Materials Characterization (MC)2. The project will utilize 316 stainless steel, known for its steady-state swelling response at high damage doses, as a test material.

This project is part of a broader initiative by the U.S. Department of Energy’s Office of Nuclear Energy, which awarded 33 Rapid Turnaround Experiment (RTE) projects in the latest call, totaling approximately $1.9 million. These projects aim to provide fundamental insights into the performance of nuclear materials under irradiation, supporting the development of advanced nuclear reactors.