NERS collaborates with INL and industry partners to advance innovative heat exchanger technology for harsh environments

Professor Stephen Raiman will head the research efforts for NERS in the DOE-funded project.

Professor Stephen Raiman will head the research efforts for NERS in the DOE-funded project.

NERS will support an Idaho National Laboratory (INL)-led research project aiming to develop highly efficient heat exchangers capable of withstanding ultra-high temperatures, built with refractory metal alloys known for their exceptional resistance to high temperatures and extreme environments. These advanced heat exchangers will incorporate cutting-edge multimodal sensors, enabling real-time structural health monitoring in the harshest environments.

“Heat exchangers have particularly demanding materials requirements,” said Prof. Stephen Raiman, who will lead NERS efforts on the project. “By utilizing the latest manufacturing methods, we free ourselves from the constraints of traditional manufacturing and open new design spaces that enable the use of optimized geometry and high-performance materials.”

The project is led by Xinchang Zhang (INL). In addition to Raiman, other collaborators on the project include Jorgen F. Rufner (INL), Michael D. McMurtrey (INL), Yanliang Zhang (University of Notre Dame), Raymond Weitekamp (polySpectra) William T. Guiney (Artic Solar, Inc.).

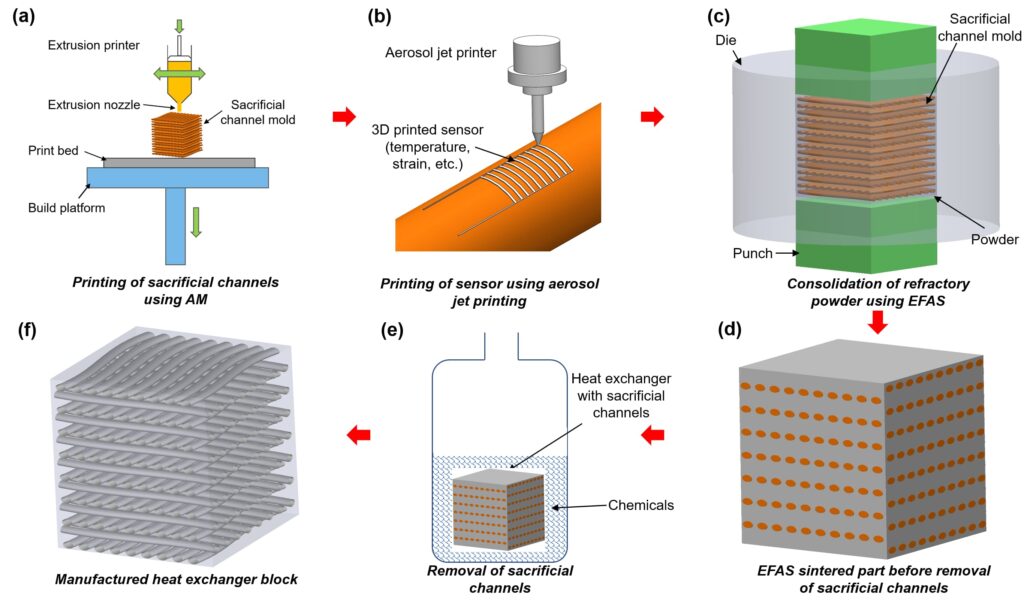

The team will use innovative manufacturing approaches to improve energy efficiency and durability, including hot isostatic pressing, and precise sensor printing techniques using additive manufacturing. They’ll also create materials able to work at very high temperatures using an advanced manufacturing process called electric-field assisted sintering, which uses heat generated by an electric field to compact powdered materials into a solid form.

Students in Raiman’s group, Materials in High-Temperature Extreme Environments (MiHTEE) Lab, will also support the research.

“Our students will be employing cutting-edge manufacturing methods and training on state-of-the-art equipment as they push the boundaries of manufacturing and materials technology in our quest for better, safer, and more affordable clean energy,” said Raiman.

This project was selected as one of the 31 projects funded by the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy. These projects aim to accelerate RD&D in domestic manufacturing, with a particular focus on next-generation materials and manufacturing technologies. The overarching goal is to strengthen America’s economic competitiveness and drive the nation toward a net-zero carbon economy by 2050.

“The greater reliability and efficiency realized by the innovations can help to make evolutionary steps toward lowering the costs of clean energy technologies like advanced nuclear and concentrating solar,” said Raiman.