NERS researchers aim to understand the behavior of high entropy alloys under extreme conditions

The research is part of a greater project to find an optimized radiation-tolerant material.

The research is part of a greater project to find an optimized radiation-tolerant material.

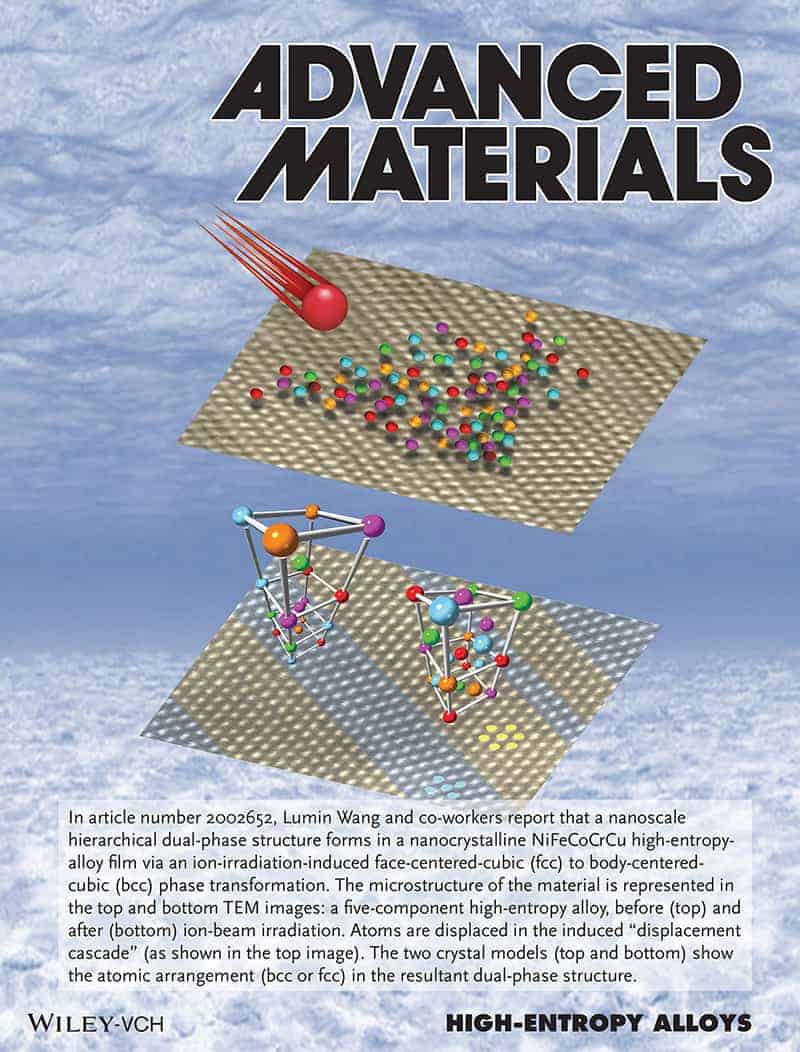

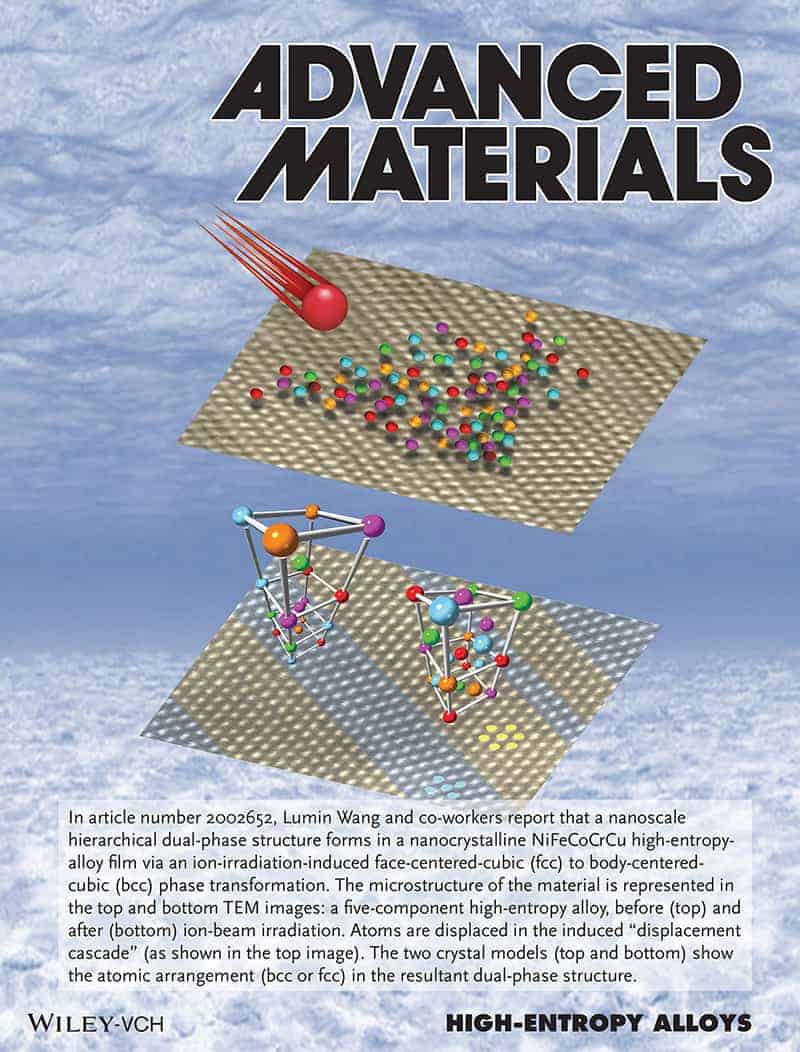

A research team from the U-M Department of Nuclear Engineering and Radiological Sciences (NERS) has used ion beams and transmission electron microscopy (TEM) to study the radiation tolerance of single phase high entropy alloys (HEA). They recently discovered the formation of nano-scale laminating, or alternating layers, of two different crystals: face-centered-cubic (fcc) and body-centered cubic (bcc) in an ion irradiated HEA that had some preexisting stacking faults.

The layering structure found by the research team, led by NERS Professor Lumin Wang, a professor of nuclear engineering and radiological sciences and materials science and engineering, should make the material stronger, more ductile and more radiation resistant. The team set out to understand the behavior of HEA under extreme conditions, such as in advanced nuclear reactors, as part of a project to find an optimized radiation-tolerant material.

“Think of a sandwich,” Wang said. “Bread, meats, or vegetables alone might not be as ideal or tasty as a sandwich with all the ingredients sandwiched (laminated) together.”

Through further testing on physical and chemical properties, Wang expects to eventually use this type of material in advanced nuclear reactors or other advanced devices that require the combination of properties from both fcc and bcc materials.

The paper on this research, titled, “High‐Entropy Alloys: Irradiation‐Induced Extremes Create Hierarchical Face‐/Body‐Centered‐Cubic Phases in Nanostructured High Entropy Alloys,” was recently published in the high-impact journal Advanced Materials with a highlighted frontispiece. The paper is the result of a collaboration between Wang’s group and several others. Professor Liang Qi’s group at the U-M Department of Materials Science and Engineering ran the computer simulation that helped to explain their experimental result. Dr. Yanwen Zhang and William Weber, both of Oak Ridge National Laboratory and University of Tennessee – Knoxville, processed the material.

Dr. Li Jiang, a research fellow in Wang’s group at NERS and the first author of the paper, made the main discovery using TEM with the help of Dr. Kai Sun in Michigan Center for Material Characterization (MC2).

The research was supported by the US Department of Energy via the Energy Frontier Research Center (EFRC) on Energy Dissipation to Defect Dissipation.

Wang’s group and collaborators have published dozens of research papers on the related subject in recent years. The following are some examples for additional reading: